Which size ground protection ground protection matss do I need?

Your ground protection mats size depends on the general type of traffic used on the ground protection mats. Both ground protection mats sizes have been tested to the same weight and load capacities. The following will assist you in choosing the right size matsting for your application, although this should only be used as a guide;

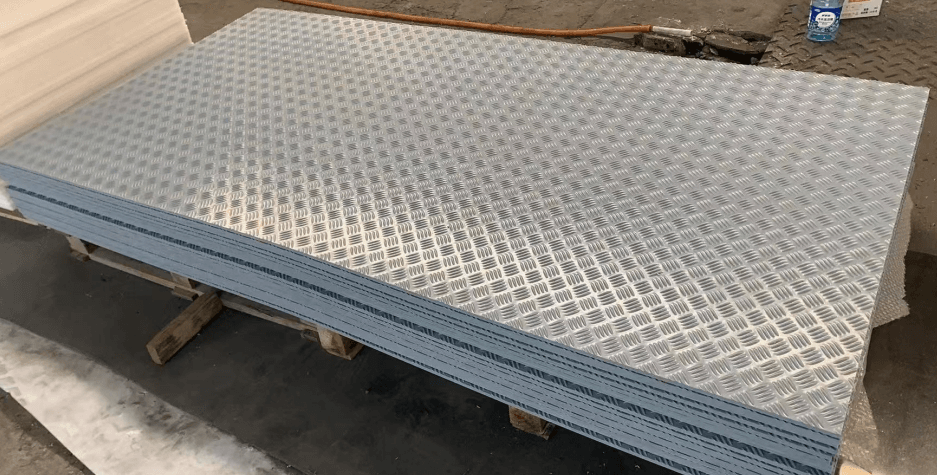

- 4×8′ ground protection mats have the broadest use rangeand are used for everything from large construction equipment to wheelbarrows.

- 3×8′ ground protection mats are desirable when price, weight, and space are a consideration.This size ground protection mats can be more restrictive with maneuvering, it is rated for the same performance as a 4×8’.

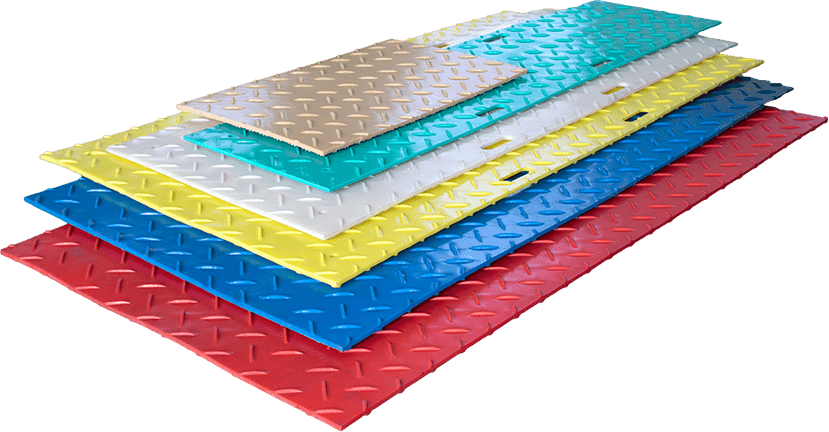

Four claw texture & Smooth textured sides – Which should I use and where?

Use the smooth side of our ground protection mats when it’s necessary to protect impressionable surfaces such as grass, concrete, asphalt, and pavers. Using a four claw texture on hot asphalt could leave marks. When making tight turns with wheeled or track equipment, it’s more desirable to use a ground protection mats with one smooth side facing up. When piling soil or aggregate on top of mats it’s also easier to use a smooth-sided ground protection mats for removal. A four claw texture will always give you the best traction in any situation!

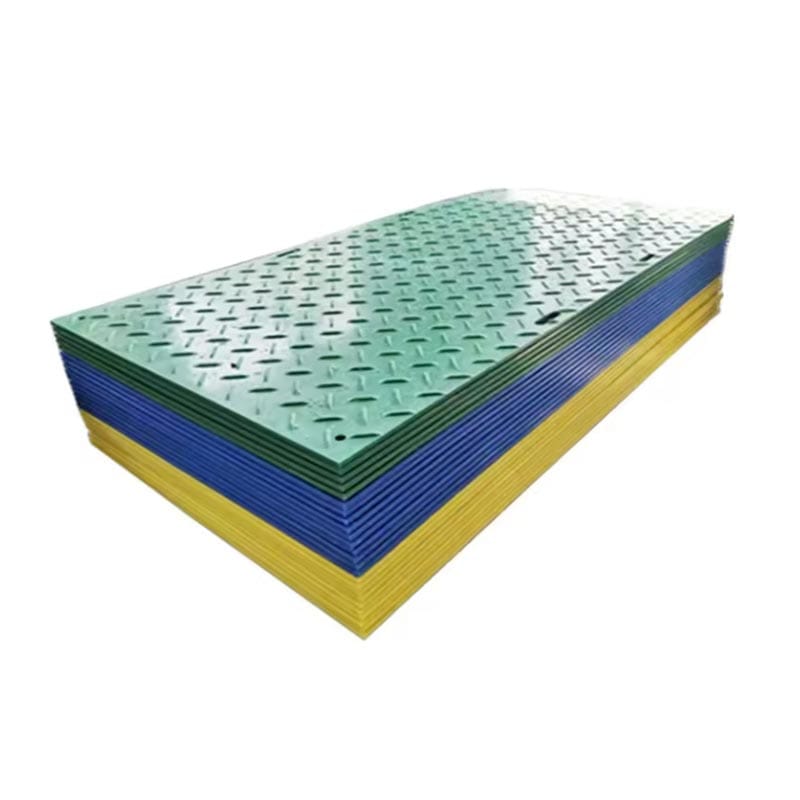

Black or Natural (White) colored ground protection mats?

- Black – If you’re using ground protection mats in the dirt or on unclean substrates, a black ground protection matswill hide the mess of a busy work or construction site.

- White – Ideal for use on manicured surfaces such as grass or turf. White ground ground protection mats reflect more sunlight and prevent “browning” of the grass by heat if used over extended periods of time.

Do I need connectors?

They’re not required but recommended if you have installed your ground protection matss on uneven ground or plan on having your ground protection matss deployed for extended periods of time.

Overmount or Undermount Connectors?

Overmount connectors are less expensive and can be used where protrusion by the connector is not critical. e.g. you only have construction equipment running over the ground protection matss with no pedestrian use.

Undermount connectors are installed from underneath the ground protection matss. They are considered to be faster and easier to install that has a flush fitting with only the nut exposed on top.

4-Way or 2-Way Connectors?

Generally used in combination depending on your ground protection mats layout configuration. 2-way type connectors are used to connect ground protection matss end to end on either side of the ground protection mats for a continuous run, e.g. two sets of tracks for construction vehicle equipment.

4-way connectors can be used to link 4 ground protection matss together by each corner to create a platform or larger working surface area.