For a 6-ton excavator, HDPE construction mats with specific design features and material properties are ideal. Here’s a detailed breakdown of the most suitable options, supported by industry standards and practical applications:

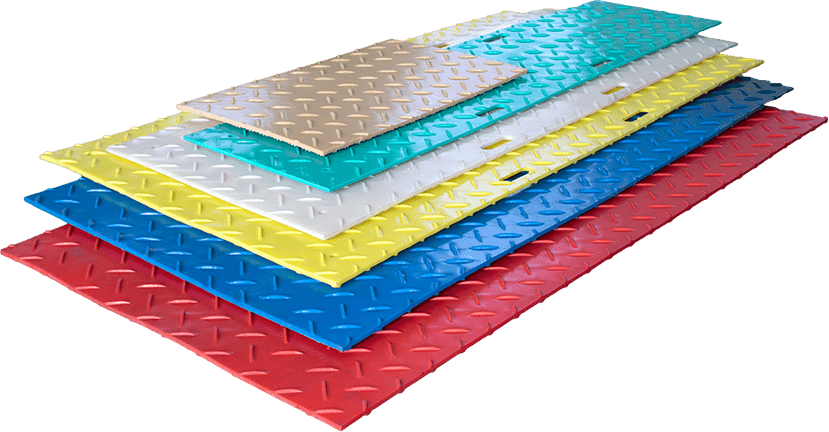

1. Portable and easy to carry HDPE Mats with Small machinery Load Capacity

Key Specifications:

- Thickness:10mm or few. For short-term use or when walking on rough terrain, it is recommended to use a 10mm mats.

- Load-Bearing Capacity: Mats should support 10–20tons to ensure safety and durability.

- Material: Virginor recycled HDPE offers superior strength and resistance to cracking under heavy loads.

Why It Works:

- HDPE’s high tensile strength (81–130 MPa) ensures the mat distributes the excavator’s weight evenly, preventing ground damage

- Virgin HDPE mats resist UV degradation, moisture absorption, and chemical corrosion, making them suitable for outdoor and harsh environments.

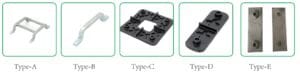

2. Interlocking Design for Stability

Features to Prioritize:

- Connectors:Mats with Metal or plastic material, 2-way or 4-way create a seamless, non-shifting surface. This prevents lateral movement under the excavator’s tracks.

- Additional steel or plastic clips (e.g., flat or round links) can further secure mats, especially on slopes or uneven ground.

Why It Works:

- A tight interlock system ensures the mat stays in place during operation, reducing the risk of equipment slippage or mat displacement.

- Easy assembly without tools speeds up deployment, critical for time-sensitive projects .

3. Anti-Slip Surface Textures

Surface Patterns:

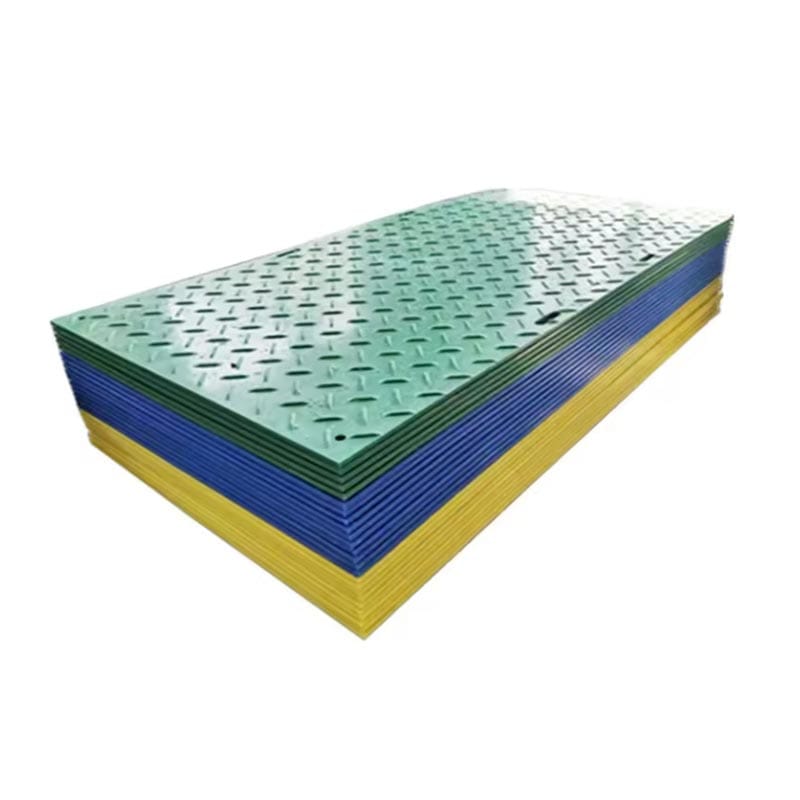

· Ribbed or Diamond-Tread Patterns: These enhance traction on wet, muddy, or snowy surfaces. For example,mats feature a bold cleat design to prevent skidding.

- · Textured Finish: Mats like Qingdao Waytop’s HDPE mats have raised diamond patterns that improve grip for both tracked and wheeled equipment.

Why It Works:

· Anti-slip surfaces reduce the likelihood of accidents and equipment instability, particularly in slippery conditions.

· The texture also helps channel water away, maintaining stability during rainfall.

4. Lightweight yet Durable Construction

Weight and Handling:

- Portability: HDPE mats are significantly lighter than steel or wood alternatives. For instance, a 4×8 ft HDPE mat (10mm thick) weighs 32kg, making it easy to transport and install with minimal labor.

- Flexibility: HDPE mats bend to contour uneven terrain without cracking, ensuring a stable base even on slopes or soft ground.

Why It Works:

- Lightweight design reduces logistics costs and installation time, while flexibility adapts to diverse site conditions.

- Durability ensures the mats last 16+ years with proper maintenance, outperforming plywood or metal in longevity.

5. Environmental and Safety Compliance

Key Considerations:

- Recyclability: HDPE mats are fully recyclable, aligning with sustainability goals.

- Safety Standards:we are a verified manufacturer ,and certified by SGS

Why It Works:

- Recyclability reduces environmental impact, while compliance with safety standards ensures reliability in heavy-duty applications.

Conclusion

For a 6-ton excavator, HDPE mats with 10 mm thickness, max load capacity about 20 tons, interlocking designs, and anti-slip surfaces are optimal. that offer reliable solutions that balance durability, safety, and ease of use.