Crane outrigger pads are essential safety accessories that provide stability and support for cranes and other heavy lifting equipment on job sites. Choosing the right outrigger pads is crucial to ensure safe and efficient operations. In this article, we’ll explore the various types of crane outrigger pads available in the market, their unique characteristics, and their specific uses to help you make an informed decision for your lifting operations.

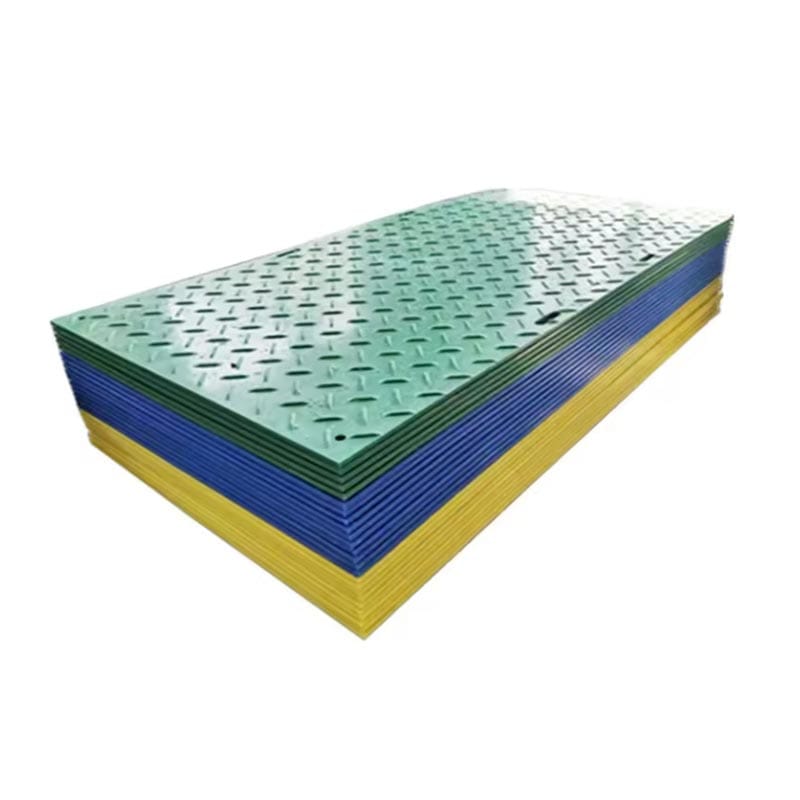

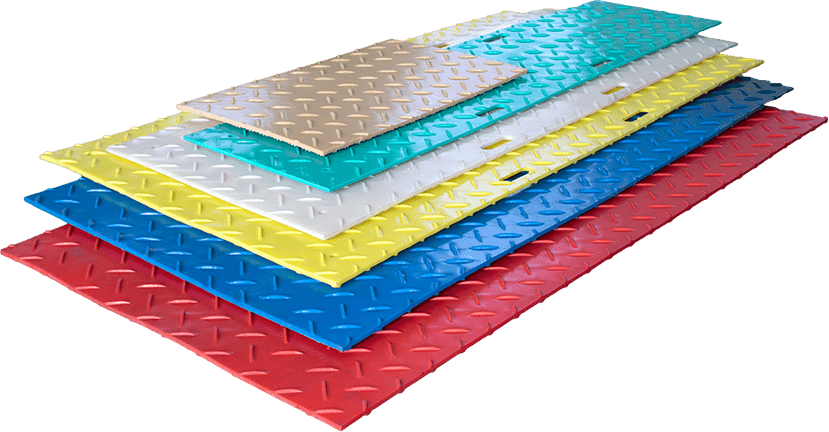

- High-Density Polyethylene (HDPE) Outrigger Pads: HDPE outrigger pads are among the most popular options due to their lightweight, durable, and versatile nature. These pads are resistant to corrosion, chemicals, and UV exposure, making them ideal for use in a wide range of environments, including construction sites, utility maintenance, and industrial applications. HDPE outrigger pads offer excellent load-bearing capacity while being easy to handle and transport, making them a preferred choice for crane operators looking for reliability and performance.

- Composite Outrigger Pads: Composite outrigger pads are made from a blend of materials such as fiberglass, resin, and other synthetic compounds. These pads offer enhanced strength, stiffness, and durability compared to traditional materials like wood or rubber. Composite outrigger pads are resistant to moisture, chemicals, and temperature fluctuations, making them suitable for use in harsh conditions. They provide superior load distribution and stability, making them ideal for heavy-duty lifting operations in construction, mining, and oil and gas industries.

- Rubber Outrigger Pads: Rubber outrigger pads are known for their flexibility, impact resistance, and non-slip properties. These pads are made from high-quality rubber compounds that offer excellent traction and stability on various surfaces, including concrete, asphalt, and gravel. Rubber outrigger pads are particularly useful in urban environments and sensitive areas where minimizing surface damage is essential. They are available in various thicknesses and sizes to accommodate different crane models and load requirements.

- Timber Outrigger Pads: Traditional timber outrigger pads are still widely used in certain applications due to their affordability and availability. These pads are typically made from hardwoods such as oak, maple, or beech, which offer decent load-bearing capacity and resistance to wear. However, timber outrigger pads are prone to moisture absorption, rotting, and splintering over time, which can compromise safety and performance. While suitable for light-duty lifting tasks, timber outrigger pads may require more frequent inspection and replacement compared to modern alternatives.

- Custom Outrigger Pads: In addition to standard options, many manufacturers offer custom outrigger pads tailored to specific requirements and preferences. Custom pads can be fabricated to precise dimensions, shapes, and configurations to fit unique outrigger setups and load conditions. Whether you need pads with reinforced corners, integrated handles, or color-coded markings, custom outrigger pads provide flexibility and versatility to meet your exact specifications. Working with a reputable supplier ensures that you get high-quality, custom solutions designed for optimal performance and safety.

Conclusion: Crane outrigger pads come in various materials, sizes, and designs, each offering specific benefits and applications. Understanding the different types of outrigger pads and their uses is essential for selecting the right pads for your lifting operations. Whether you prioritize durability, stability, versatility, or customization, there’s a wide range of options available to meet your specific requirements. By choosing the appropriate outrigger pads, you can enhance safety, efficiency, and performance on your job site while protecting your equipment and the surrounding environment.