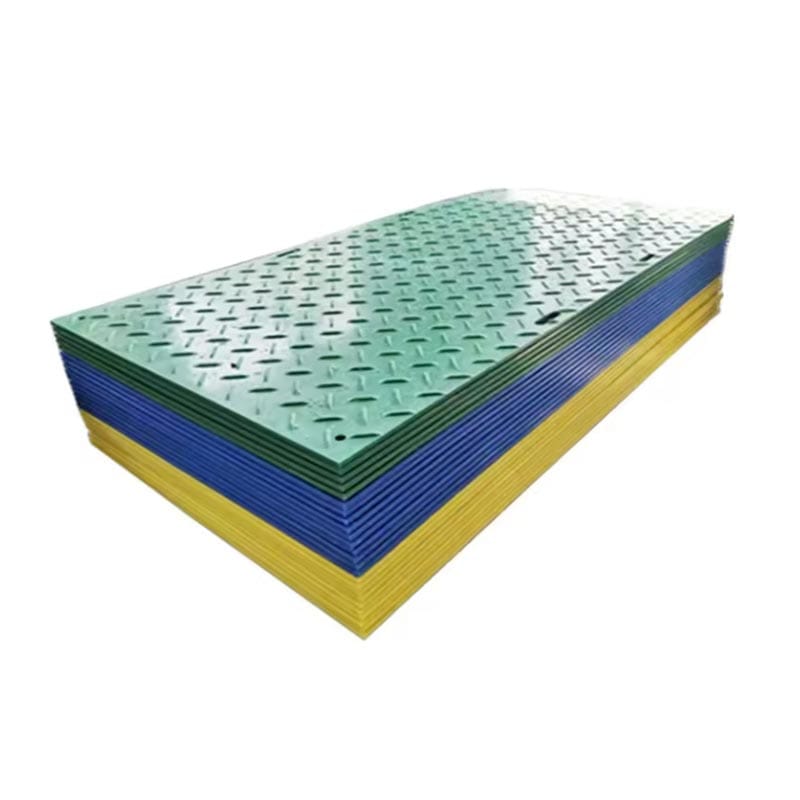

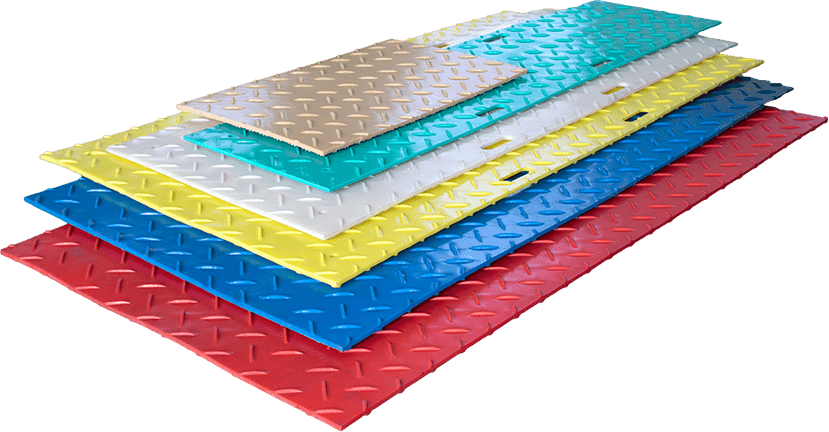

In the rumbling industrial buildings, where machines run around the clock, the ground carries an unimaginable weight. Forklifts shuttling back and forth, heavy machinery standing and roaring, raw materials and finished products are constantly loaded and unloaded, all of which cause a continuous and high intensity test on the ground. The floor protection pad, as the “invisible guard” silently sticking to the industrial plant, is playing an irreplaceable key role.

The ground protection pad first shoulders the heavy responsibility of resisting mechanical wear. In industrial plants, forklifts are the busiest “porters”, and their tires roll countless times on the ground, generating great friction. Long-term friction will make the surface of the ground wear off, and then lead to direct exposure of the cement floor, rough tires and rough cement continuous friction, the ground will soon appear potholes, scratches and other damage. The ground protection pad is generally made of high-strength, wear-resistant rubber or composite materials, which can withstand the repeated rolling of forklift tires. When the forklift is driven on the protective pad, the pad disperses friction, greatly reducing direct wear to the ground. For example, in the car factory house, there are a large number of forklifts every day to carry auto parts, and after the installation of floor protection MATS, the wear degree of the ground is significantly reduced, and the ground that originally needs to be renovated every few years is now greatly extended.

The parking and operation of heavy machinery also creates significant pressure on the ground. Like large machine tools, stamping equipment, etc., their own weight can reach several tons or even tens of tons, and they will also produce vibration when working. If placed directly on the ground, the ground is easy to sag, cracks and other problems due to overwhelming. The ground protection pad has good compressive performance, can evenly disperse the weight of the machine, and buffer the vibration generated during the operation of the machine. In a heavy machinery manufacturing factory, large processing equipment is placed on the ground protection mat, after many years, the ground is still flat, there is no sign of damage caused by the weight of the equipment, which fully reflects the effective protection of the protective mat on the ground.

In addition to mechanical factors, the loading and unloading of various raw materials and finished products in industrial plants can also cause damage to the ground. Sharp metal parts, heavy wooden boxes, etc., may hit the ground once they are dropped during handling. The floor protection mat is like a layer of strong armor, which can absorb the impact of falling objects and prevent the ground from being smashed or damaged. For example, in the electronic products manufacturing plant room, although the precision electronic components are lighter in weight, during the transportation process, the metal tray carrying the components will also cause scratches to the ground if it is accidentally dropped. The existence of the ground protection pad effectively reduces this risk and protects the integrity of the ground.

From a cost point of view, the investment of floor protection MATS is a very cost-effective initiative. Although the purchase and laying of floor protection MATS requires a certain amount of money, it is nothing compared to the cost of frequent maintenance or renovation of the ground. Ground maintenance not only needs to invest a lot of manpower, material resources and time, but also leads to plant shutdown and production, resulting in huge economic losses. The use of ground protection pads can greatly reduce the frequency of ground maintenance, ensure the continuity of plant production, and save a lot of costs for enterprises.

In industrial plants, the ground protection mat is the key to ensure the safety of the ground, extend the service life of the ground, and reduce the operating costs of enterprises. It seems ordinary, but behind the scenes of industrial production, for the efficient and stable production environment silently dedication, is an indispensable part of the industrial field.