The difficulties brought by complex terrain to drilling operations are countless.

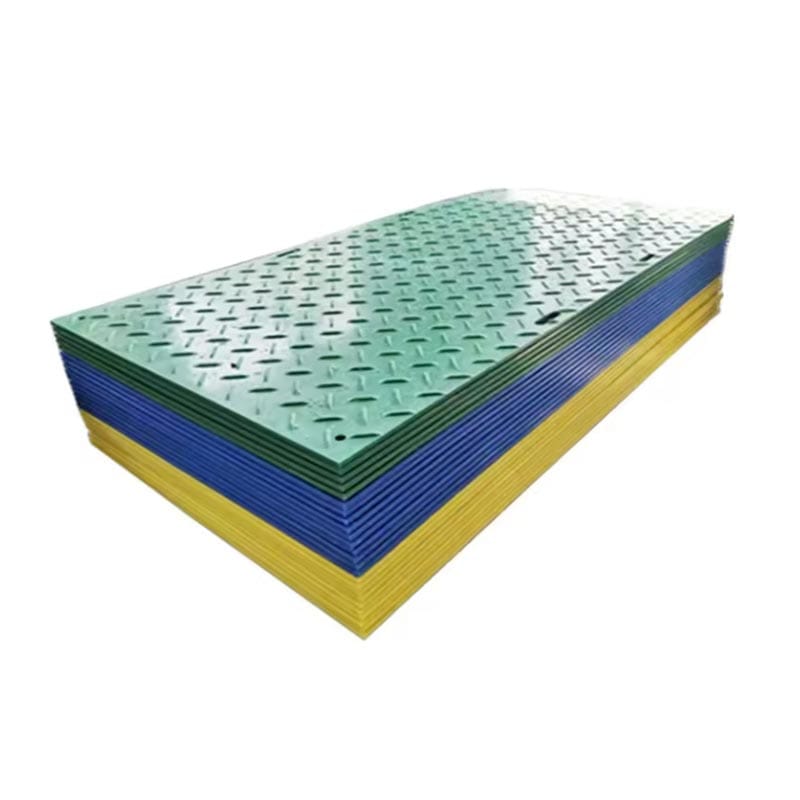

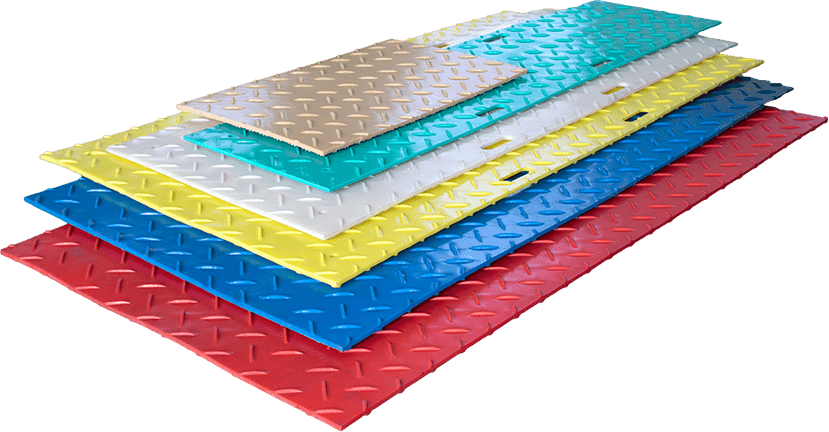

The emergence of ground protection mats provides an effective way to solve these problems. Take a drilling project in a mountainous area as an example.

In wetland drilling operations, ground protection mats also play a huge role. In a wetland oil field project, at the beginning of construction, conventional vehicles and equipment could not enter the operation area at all because the ground was too soft. The construction workers laid the ground protection mats on the wetland surface in an orderly manner, and built a stable working platform and transportation channel. With the help of these ground protection mats, large drilling equipment can be smoothly installed on site, and various material transportation vehicles can also shuttle frequently, effectively shortening the construction period of the project.

Drilling operations in desert areas, wind and sand and soft sand have always been a problem that plagues construction. The modular design allows the paving slabs to be flexibly combined according to the actual terrain and operation requirements, greatly improving the convenience of construction. During the entire drilling process, the paving slabs effectively supported the weight of the equipment and vehicles, reduced the impact of sand on the operation of the equipment, and ensured the continuous and stable progress of the drilling operation.

Drilling construction in the permafrost zone has more stringent requirements on the performance of ground protection mats. A permafrost zone drilling project uses rubber paving slabs with good cold resistance. In low temperature environments, this ground protection mats can still maintain good flexibility and strength and will not be damaged by freezing and thawing. It not only provides stable support for drilling equipment, but also reduces the direct pressure of equipment on the permafrost ground, and reduces the impact of ground deformation on equipment operation. At the same time, the laying and removal of rubber paving slabs are relatively simple, which can adapt to the strong seasonal characteristics of permafrost construction and provide a strong guarantee for the smooth implementation of the project.

In complex terrain drilling, the practical application of paving slabs has fully demonstrated its excellent value.