In the operation system of modern airport, the apron is the key area for aircraft take-off and landing, docking and various support operations, and its ground condition has a direct impact on aviation safety and operation efficiency. In this seemingly ordinary area, the ground protection mat is its low-key but indispensable presence, contributing a full range of support for the stable operation of the tarmac.

The moment when the aircraft takes off, lands and taxies is the moment when the tarmac ground faces a severe test. When the aircraft lands, the moment the landing gear contacts the ground, it bears the impact force of several tons or even tens of tons, which is equivalent to the weight of a loaded heavy truck in a short period of time. At the same time, during the taxi process of the aircraft, the friction generated by the high-speed rotating tires and the ground is far more intense than that of general transportation. Subjected to such high intensity impact and friction for a long time, the ground of the apron is easy to wear, cracks, and even the formation of potholes. These surface damage will not only affect the smoothness of the aircraft, but also may cause safety hazards, such as damage to the aircraft tire, which will affect flight safety.

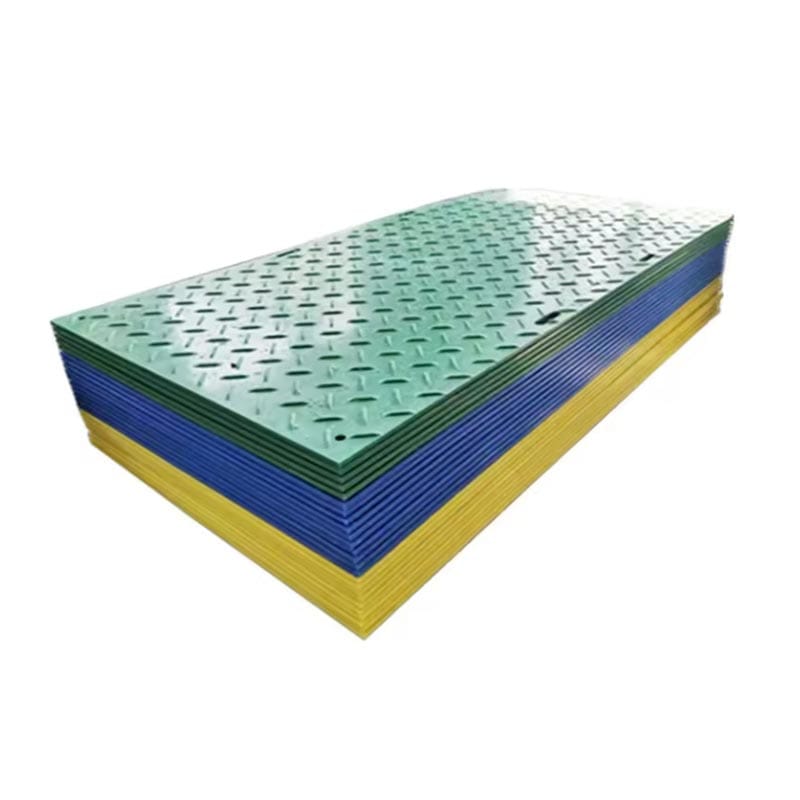

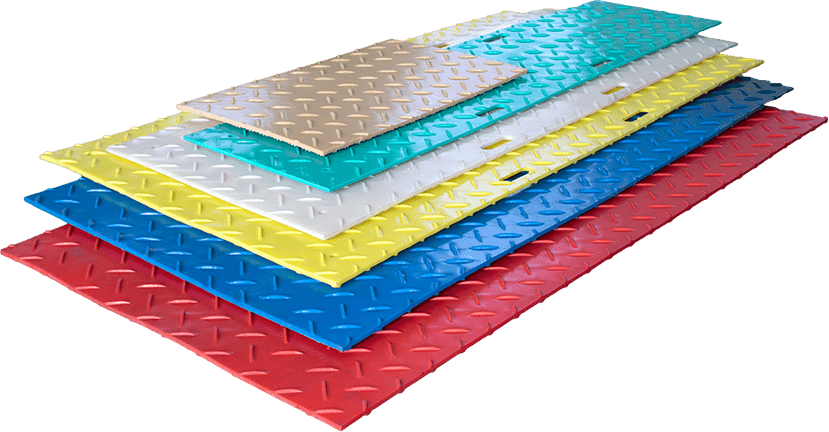

Ground protection pads are made of special high-strength, wear-resistant materials that have been carefully designed to effectively handle the challenges of aircraft takeoff, landing and taxiing. When the aircraft lands or taxies on the protective cushion, its internal material structure acts like a sophisticated pressure distribution system that evenly distributes the huge impact force over a larger ground area. This is like putting a heavy object on a soft and flexible net, the pressure is shared by all parts of the net, thus greatly reducing the pressure borne by the unit area. At the same time, the wear resistance of the protective pad makes it able to resist the friction of aircraft tires for a long time, reduce ground wear, and significantly extend the service life of the ground. In some busy international airports, aircraft takeoff and landing sorties can reach hundreds of thousands per year, the use of ground protection pads, the maintenance cycle of the ground from the original one or two years to three to five years, maintenance costs are also significantly reduced, reducing the economic burden of airport operations.

In addition to aircraft, the frequent driving of various types of support vehicles on the tarmac has also caused an impact on the ground that cannot be ignored. Fuel trucks, tractors, luggage carriers, etc., their tires are constantly worn and scratched on the ground in the day after day of driving. In addition, some vehicles in emergency braking or turning, will produce additional lateral force, which is like a “lateral pull” on the ground, further aggravating the ground damage. The ground protection pad provides a buffer layer for these vehicles, increasing the friction between the vehicle tire and the ground, improving the safety of the vehicle, avoiding collision accidents caused by skidding, and ensuring the safety of personnel and equipment on the tarmac.

In terms of environmental protection, the floor protection pad also plays a positive role. In the process of aircraft refueling, maintenance and other operations, due to complex operations and involving a large number of chemicals, the risk of leakage of fuel and lubricating oil always exists. Once these chemicals leak directly into the ground, they can quickly penetrate into the soil, contaminate groundwater, and cause long-term and difficult to repair damage to the surrounding ecological environment. The surface protective mat can effectively prevent these chemicals from seeping into the ground, and it acts as a tight protective barrier to isolate leaks at the surface. In the event of a leak, the staff can clean up the pollutants on the protection pad in time to avoid greater harm to the environment, and build a solid defense line for the ecological environment around the airport.

From an operating cost perspective, although the acquisition and laying of ground protection pads requires a certain upfront capital investment, it is only a negligible part compared to the high cost of frequent maintenance or renovation of the apron floor. Apron ground maintenance is a complex and arduous project, which not only needs to invest a lot of manpower, material resources and time, but also leads to the temporary closure of some areas of the apron. Each closure of the tarmac means flight delay or cancellation, which brings huge economic losses to the airport, including compensation for flight delay and loss of potential passenger sources caused by the decline in passenger satisfaction. In contrast, the use of ground protection pads can effectively reduce the frequency of ground damage, ensure the normal operation of the airport, save a lot of costs for the airport, and is a cost-effective long-term investment.

In the field of aviation, although it may seem ordinary, ground protection pads play a key role in ensuring ground safety, extending ground life, protecting the environment and reducing operating costs. It is the invisible guard on the tarmac, silently guarding every link of aviation operations, and is an indispensable part of modern airports.