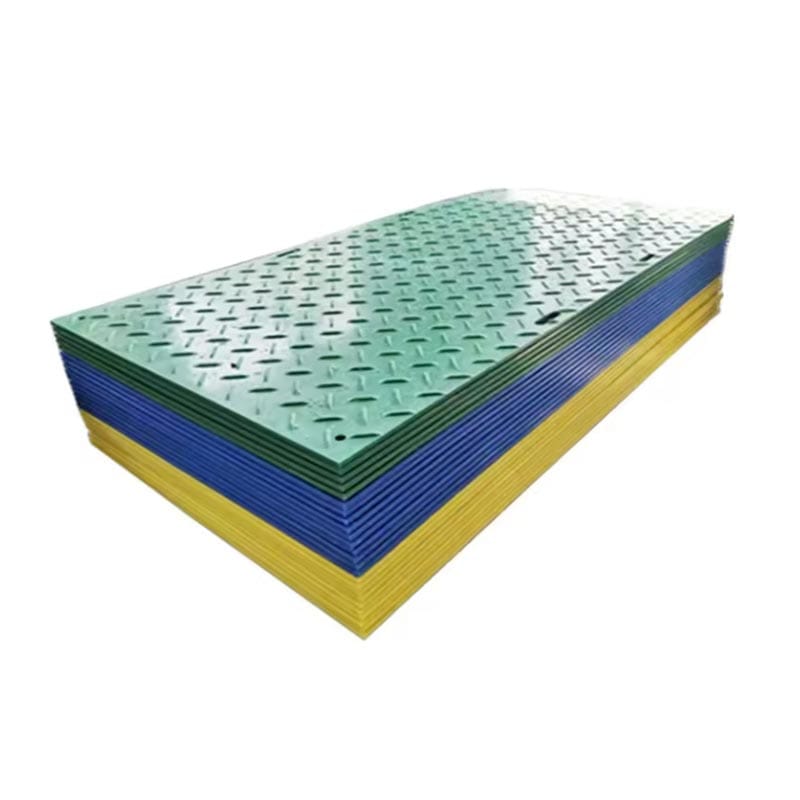

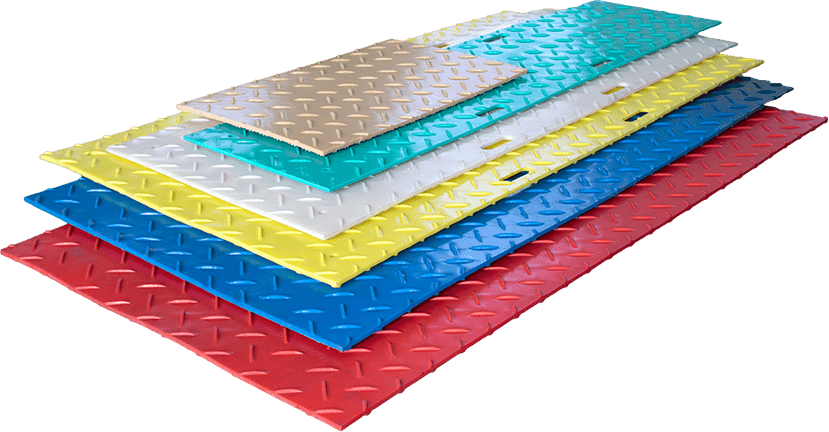

HDPE ground protection mat are a type of ground protection material widely used in construction sites, temporary roads, garden landscapes, outdoor activities and other scenes. It can not only withstand the rolling of heavy machinery, but also effectively prevent ground damage, mud and settlement, thereby improving construction efficiency and ensuring the safety of personnel and equipment. In various engineering construction and outdoor activities, paving slabs (Road Mat, Ground Protection Mat) have become an indispensable auxiliary tool.

The following are some application case analyses of ground protection mats to improve construction efficiency:

Construction of photovoltaic base in Tengger Desert, Ningxia:

Background: The terrain in desert areas is complex, and traditional paving materials are difficult to transport and prone to sedimentation. The construction of photovoltaic bases requires the transportation of photovoltaic panels and other equipment, which has high requirements for roads.

Solution: Use lightweight HDPE ground protection mats, which weigh only 1/5 to 1/7 of steel plates, greatly improving transportation efficiency. Through honeycomb structure or thickening design, a single piece can bear 50 to 100 tons, which can disperse pressure and prevent sand from settling. The surface has herringbone willow leaf pattern or diamond convex design, which has good anti-slip performance.

Effect: Rapid deployment of temporary roads ensures flexible passage of photovoltaic panel transport vehicles between sand dunes, shortening the project construction period by about 20%, while reducing the vehicle skidding accident rate by 85%, and the service life exceeds 5 years, and the maintenance cost is reduced by 60%.

Expansion project of a chemical park:

Background: Heavy equipment and vehicles are frequently used in chemical parks, and the ground is prone to muddy and dusty problems. The traditional road construction method has a long construction period.

Solution: Use PE ground protection mats, which are lightweight and easy to install. A few workers and some basic tools can complete the paving. At the same time, PE ground protection mats have high compressive strength and good temperature resistance, and can adapt to the temperature changes in different seasons and process conditions in the chemical park.

Effect: Rapid construction of temporary roads greatly shortens the construction period and improves construction efficiency. The road environment in the park has been significantly improved, and the muddy and dusty conditions have been greatly reduced, which has improved the overall image and safety of the park.

100MW photovoltaic project in Kubuqi Desert, Inner Mongolia:

Background: Desert photovoltaic construction faces difficulties such as insufficient sand bearing capacity, harsh climate and fragile ecology. Traditional paving materials are prone to aging and cracking, and construction compaction may cause irreversible ecological damage.

Solution: Use lightweight paving pads, adopt high-density polyethylene (HDPE) honeycomb structure to disperse concentrated loads, anti-ultraviolet additives to extend the life of materials, hollow structures to reduce sand compaction, and surface anti-skid textures to increase tire friction coefficients. Effect: The rate of transport vehicles getting stuck has dropped from 35% to 2%, and construction efficiency has increased by 40%. The effective construction time is extended by 2 hours/day, and the overall construction period is shortened by 25%. The vegetation coverage rate in the construction area is 18% higher than that of the traditional road section, and the life cycle cost is reduced by 45%.

220 kV power transmission and transformation project in a farmland area:

Background: The project crosses multiple fields, the terrain is complex and changeable, there are soft land and steep slopes, and the traditional road construction method cannot meet the needs. Solution: The construction party uses high-strength ground protection mats to provide a stable passage and operating platform for construction personnel and equipment. Effect: Rapidly build a stable construction channel and operating platform, ensure the smooth passage of heavy equipment, reduce damage to farmland, and provide a strong guarantee for the smooth progress of the project.

Oilfield construction in the Canadian oil sands area:

Background: The oilfield construction environment is complex, the equipment load is large, and traditional ground materials are difficult to meet the needs.

Solution: Use multifunctional polyethylene paving pads, which can withstand 40 tons to 200 tons per square meter. It is corrosion-resistant, non-slip, light and easy to install, and has strong weather resistance.

Effect: It successfully supported an 80-ton vehicle, with ground settlement being only 1/3 of that of traditional methods, a service life of 5 to 8 years, and a full life cycle cost that is 40% to 60% lower than traditional pads, shortening the construction period and reducing transportation and construction costs.