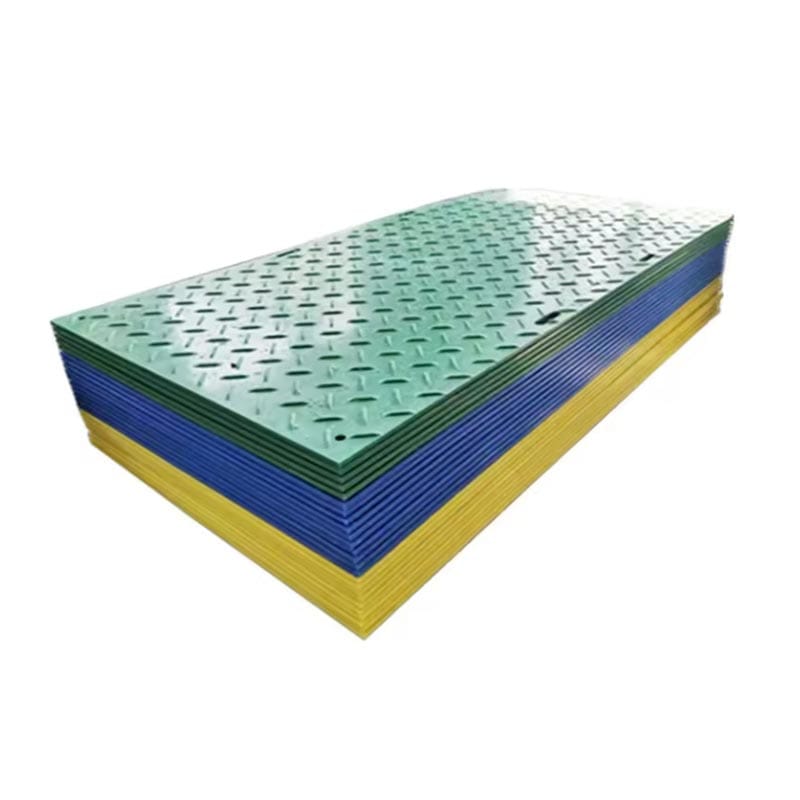

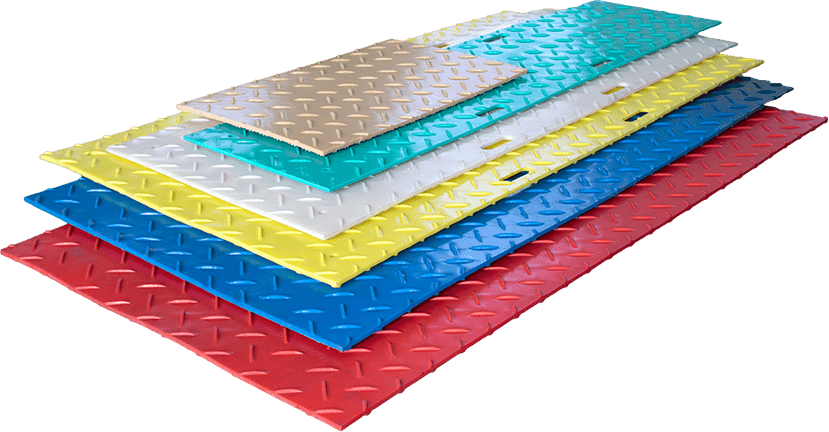

HDPE road mats, also known as paving boards, are essential tools in a wide variety of projects, ranging from construction sites to large – scale outdoor events. As a leading factory specialized in manufacturing high – quality HDPE road mats, we not only provide top – notch products but also offer valuable guidance on their correct installation.

Step – by – Step Installation Process

1.Site Preparation

Before laying the HDPE road mats, it is of utmost importance to clear the area of all debris, rocks, or sharp objects. These can damage the mats and reduce their effectiveness. Level the ground as much as possible. If there are significant dips or bumps, filling them with suitable soil or gravel can create a more stable base.

2.Mat Selection and Layout Planning

Our factory offers a diverse range of HDPE road mats to meet different needs. Consider the weight of the equipment or vehicles that will be using the area. For heavy – duty applications, such as construction sites with large earth – moving machinery, our high – strength mats made from high – quality, wear – resistant materials are the ideal choice.

Plan the layout of the mats. Start from one end of the area to be protected and work your way across. Try to create a pattern that maximizes coverage and minimizes gaps. In most cases, a simple interlocking or side – by – side layout works well.

3.Laying the Mats

Lift the HDPE road mats carefully. They are designed to be relatively lightweight for easy handling, but proper lifting techniques should still be used to avoid injury. Place the first mat firmly on the prepared ground.

For interlocking mats, align the edges of the adjacent mats and push them together until they lock securely. This interlocking feature not only makes installation easier but also ensures a stable and continuous surface. If using non – interlocking mats, place them side by side with minimal gaps between them.

4.Securing the Mats

In some cases, especially in areas with high wind or where there will be a lot of movement, it may be necessary to secure the mats. Our mats can be anchored to the ground using stakes or other fastening methods. Make sure the stakes are driven deep enough into the ground to hold the mats in place.

Tips and Precautions

1.Pay Attention to Surface Conditions

During and after installation, pay attention to the surface conditions of the mats. If the mats are placed on wet or muddy ground, they may shift over time. Regularly check for any signs of displacement and readjust as needed.

2.Weight Distribution

When using the area with the laid mats, ensure proper weight distribution. Avoid concentrating all the weight in one small area of the mats, as this can cause them to sink or become damaged. Our mats are designed to evenly distribute weight, but following good practices helps maintain their integrity.

3.Maintenance and Cleaning

After the project is completed, clean the HDPE road mats before storage. Remove all dirt, mud, or debris. This not only keeps the mats in good condition for future use but also makes them easier to handle. Store the mats in a dry, well – ventilated area to prevent mold and mildew growth.

By following these steps and tips, you can ensure the effective installation and long – term use of our HDPE road mats. Our factory is committed to not only providing high – quality products but also comprehensive support to help you achieve the best results in your projects. Whether it’s protecting a construction site, creating a safe passage for an outdoor event, or any other application scenario, our HDPE road mats are your reliable choice.