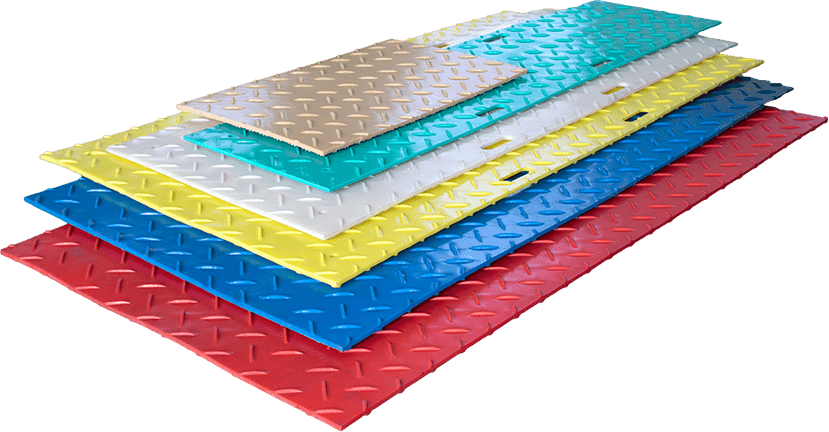

The difference between laying construction mats with metal and plastic connectors.

Construction mats can protect the ground from heavy machinery and pedestrians.

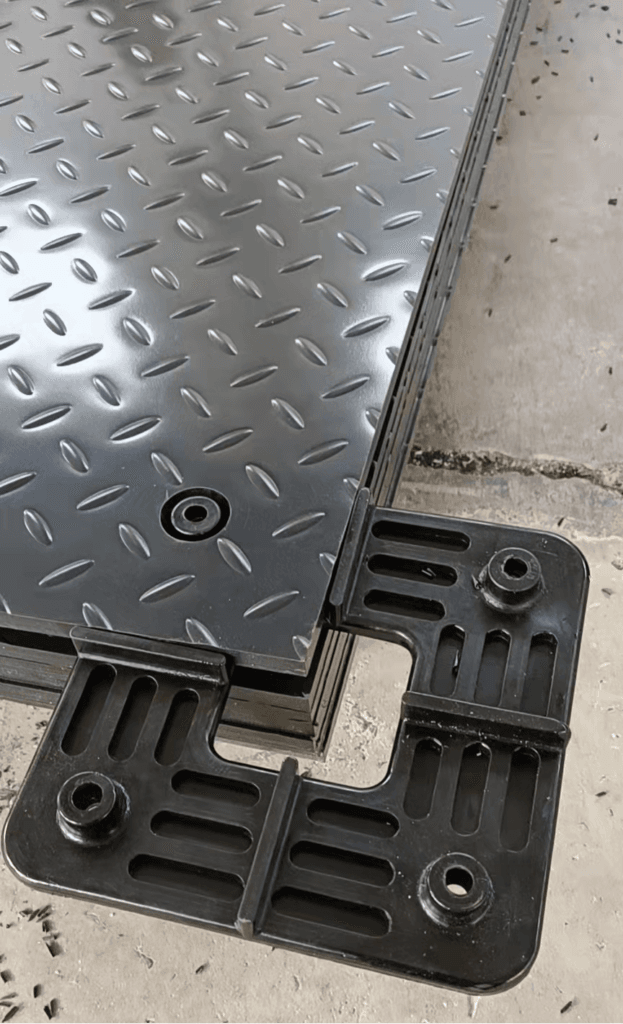

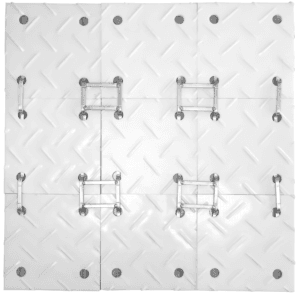

Connectors are indispensable in providing connection performance and stability.

Now mainly introduce the differences between metal and plastic connectors, mainly in the following aspects:

Durable and load-bearing

Metal connectors are usually made of steel and are very durable. They can bear the continuous heavy load of large-scale construction equipment. Such as concrete mixers and cranes, will not bend or break.

In contrast, plastic connectors, which are usually made of polymers such as polyethylene, are more suitable for light to medium loads.

Installation and disassembly process

The installation process is very simple, suitable for both metal and plastic forms. Just insert the connector into the corresponding hole, usually takes less than 5 seconds. Similarly, disassembly is as simple as removing the connector from the hole. Both installation and disassembly processes offer similar levels of convenience.

Metal connectors are usually more expensive. The cost of raw materials (such as steel) and the manufacturing process involved in the production of metal connectors lead to its price increase. Plastic connectors are made of cheaper materials and simpler manufacturing process, which is more economical and friendly. This makes plastic connectors an attractive choice for projects with tight budgets.

Weather fastness

Metal connector, made of stainless steel, is not easy to deform and break, and can withstand rain, snow or extreme poor weather conditions.

The plastic connector is made of HDPE, which more wear-resistant and is not easy to corrode.

In a word, metal and plastic connectors depend on users adapting to their own application scenarios and weighing the benefits to make their own choices.

General suggestion: both metal and plastic are flexible, quick to install, disassemble and portable. Metal connector is an ideal choice for heavy-duty and long-term projects, which is more durable and costs a little more than plastic. Plastic connectors have lower cost and are more suitable for light and short-term construction work.