When choosing ground protection mats, you need to consider factors such as the use environment, load-bearing requirements, wear resistance and anti-skid properties. The following is a specific selection method:

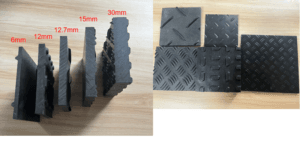

- How to choose the thickness of the ground protection mat?

The thickness of the ground protection mat mainly depends on the load-bearing capacity and the use scenario:

Light load scenario (sidewalks, temporary trails): 10-15mm thick ground protection mats are sufficient to meet basic walking needs.

Medium load (small vehicles, construction sites): 15-25mm thickness is recommended to withstand the rolling of light machinery and vehicles.

Heavy load scenario (large machinery,truck traffic): at least 25-50mm thick to ensure compression resistance and durability to prevent damage.

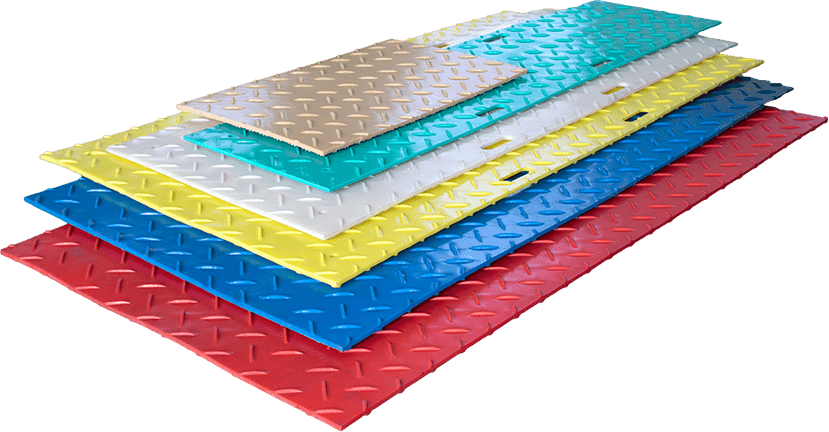

- How to choose the pattern of the ground protection mat?

The pattern of the ground protection mat mainly affects the anti-skid performance and drainage capacity:

Pedestrian walkways and landscape trails: It is suitable to choose small anti-skid patterns (such as stripes and dot patterns), with moderate anti-skid effect, suitable for walkers.

Construction sites and construction site roads: Herringbone patterns are recommended to increase friction and are suitable for muddy or slippery environments.

Roads for heavy vehicles: Large grids or corrugated patterns are recommended to provide stronger anti-slip performance, wear resistance and pressure resistance.

- How to choose the material of ground protection mats?

Different materials are suitable for different application environments:

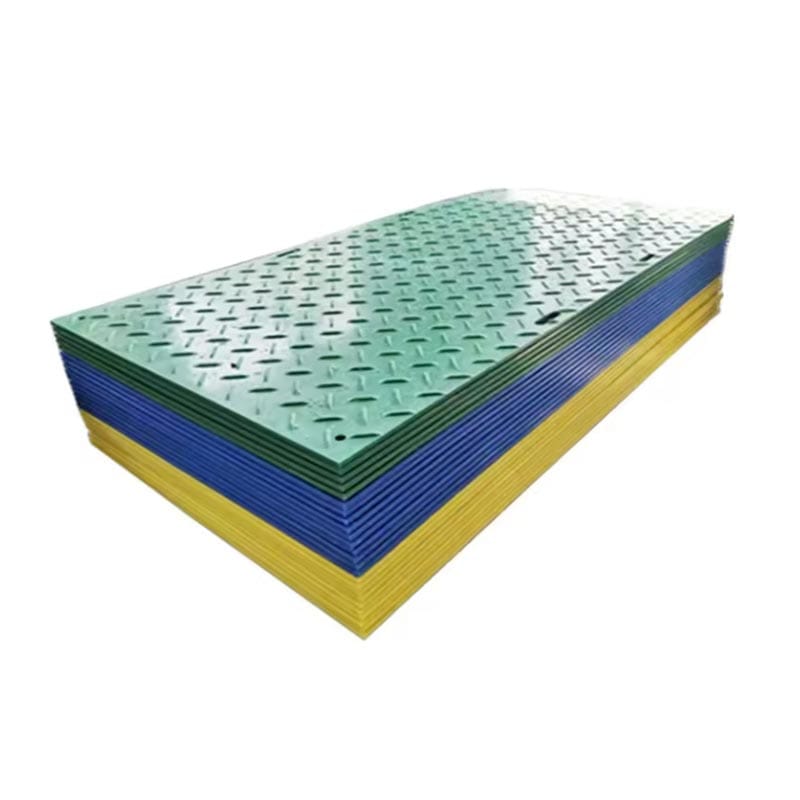

Plastic ground protection mats (HDPE/composite plastics):

Advantages: light, corrosion-resistant, anti-slip, easy to clean, suitable for temporary roads, lawn protection, etc.

Disadvantages: relatively weak bearing capacity, not suitable for super-heavy vehicles.

Steel plate ground protection mats:

Advantages: strong load-bearing capacity, suitable for construction areas where heavy equipment passes.

Disadvantages: easy to rust, heavy weight, and more troublesome to lay and disassemble.

Rubber ground protection mats:

Advantages: good elasticity, impact absorption, suitable for sidewalks, fitness trails, etc.

Disadvantages: not resistant to high-intensity rolling and easy to age.

Concrete ground protection mats:

Advantages: wear-resistant, pressure-resistant, long life, suitable for permanent roads.

Disadvantages: Complex construction and not flexible to move.

Summary

When choosing a ground protection mat, first determine the usage scenario and load-bearing requirements, and then choose the appropriate thickness, pattern and material. If it is a short-term construction or light load requirement, plastic or rubber materials can be selected; if heavy equipment is passing, it is recommended to use steel plates or thickened concrete ground protection mats.