Construction mats are vital for construction and industrial work.

They offer a stable surface, safeguard the ground, and support heavy equipment movement.

When picking construction mats, the desired load bearing capacity, closely tied to mat thickness, is a key factor.

Understanding Load Requirements

First, accurately figure out the load the mats will bear.

This includes the weight of construction machinery such as bulldozers, cranes, and dump trucks, as well as any additional loads from building materials or stacked gear.

A small residential project with light – duty machines has much lower load needs than a large – scale commercial site with big earth – moving equipment.

You also can tell our sales staff directly what bearing range you want the mats to have (about ? tons), and then we recommend the corresponding thickness

The Significance of Mat Thickness

Typically, thicker mats can bear more weight.

They have more material, which spreads the load over a larger area and resists bending better.

A 1/2 – inch thick mat might be fine for light – duty uses like pedestrian traffic and small tool movement.

But for heavy – duty jobs with large cranes or fully – loaded trucks, 3/5 – inch – thick or thicker mats are often needed.

These thick mats can handle intense pressure and stop the ground from sinking.

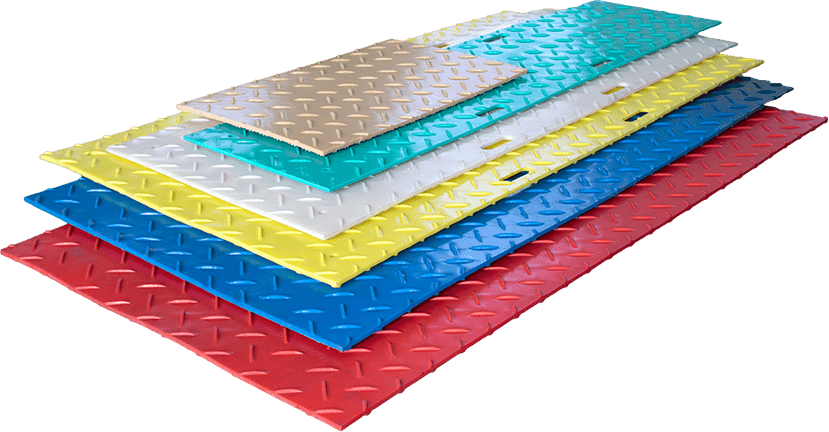

Material Considerations in Conjunction with Thickness

The mat material also affects its load – bearing capacity relative to thickness.

Mats are often made from synthetic stuff such as high – density polyethylene (HDPE).

HDPE mats are tough and long – lasting,their strength means a thinner hard mat can still handle heavy loads.

HDPE mats are lightweight but distribute load well.

To match the load – bearing, HDPE mats might need to be a certain thickness.

Environmental and Site – Specific Factors

Environmental conditions and the site itself impact mat thickness choice.

On soft or marshy ground, a thicker mat is required to keep support and stop sinking, even with light equipment.

On firm, compact soil, a thinner mat may be enough.

If the site gets a lot of rain or is moist, the mat’s thickness and material should resist water damage and keep its load – bearing ability.

In short, choosing the right mat thickness for the desired load bearing involves carefully looking at load requirements, understanding how thickness relates to load – bearing, considering the material, and assessing environmental and site factors.

By doing this, construction workers can ensure project safety and efficiency while making a cost – effective mats choice.