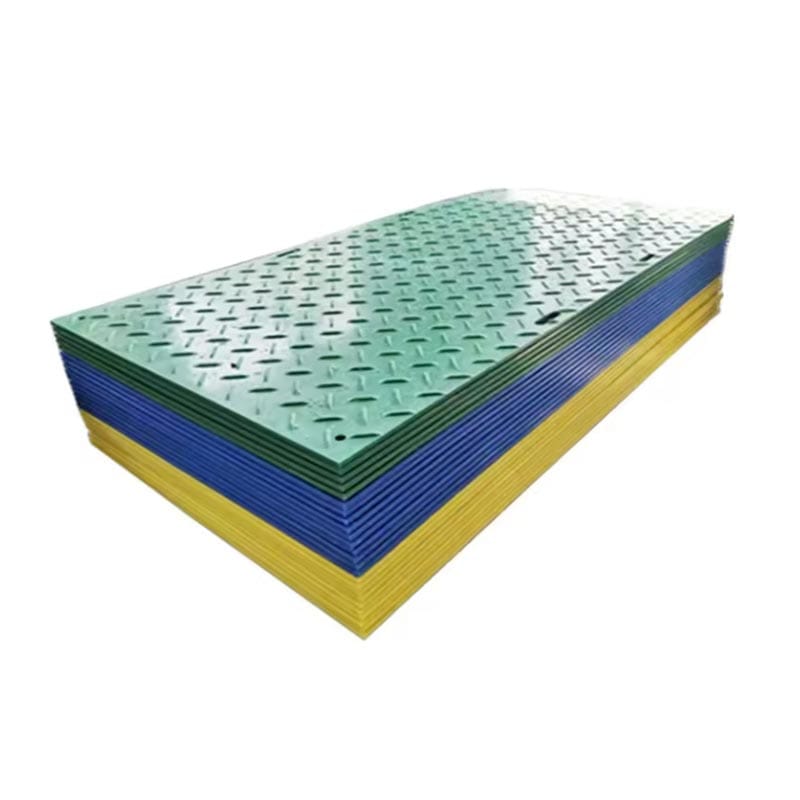

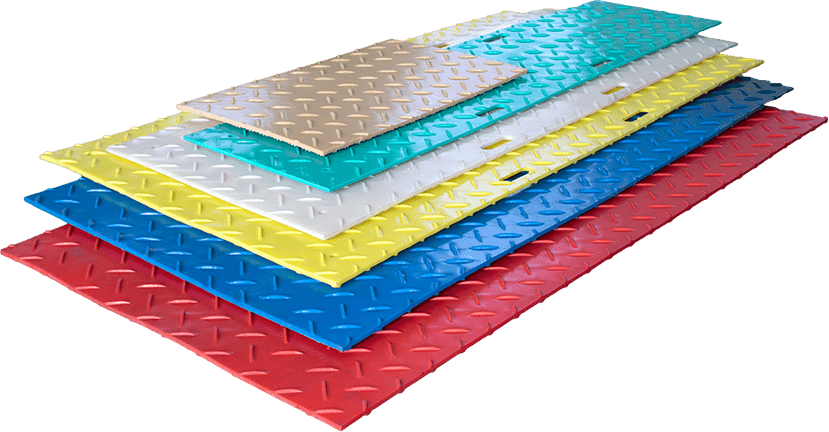

Ground protection mats are an essential tool in various industries, particularly in construction, events, and road repair. Their versatility and effectiveness are especially evident in emergency road repairs, where the need for fast, efficient, and safe work is critical. These mats provide an array of advantages, making them an invaluable asset for emergency response teams and contractors. In emergency road repair, ground protection mats show good durability.

In terms of materials, they are usually made of high-strength materials. For example, many ground protection mats are made of composite plastics, such as high-density polyethylene (HDPE),Ultra high molecular weight polyethylene(UHMWPE). These materials have strong wear resistance and can withstand huge friction without breaking easily during the frequent movement and rolling of heavy equipment. Even in the complex and high-intensity use environment of emergency road repair sites, such as large cranes, loaders and other equipment shuttling back and forth, it can resist the friction of equipment tracks or wheels and maintain its integrity for a long time.

In terms of load-bearing capacity, ground protection mats are designed to withstand considerable weight. Generally speaking, high-quality ground protection mats can withstand several tons or even hundreds of tons per square meter. In emergency road repair, there may be various heavy equipment working at the same time, such as excavators digging damaged roads and dump trucks transporting repair materials. These mats can stably carry these equipment and will not be damaged due to excessive weight at one time. For example, when repairing mountain roads damaged by landslides, it can support the weight of the equipment well and can be used repeatedly even if a large bulldozer is working on it.

The ground protection mat also performs well in dealing with different environmental factors. In severe weather conditions, such as heavy rain, the ground may become muddy, and it can prevent it from being soaked in mud and water and losing its performance. In high temperature environments, it will not deform or soften due to long-term exposure to the sun. In addition, in some emergency road repair scenarios where chemicals may leak (such as roads where vehicles transporting dangerous chemicals have accidents), it can resist a certain degree of chemical corrosion and ensure its durability.

However, the durability of the ground protection mat will also be affected by factors such as usage time, frequency, and equipment weight. If it is used for a long time beyond its load limit, or the use environment is too harsh (such as frequent chemical corrosion such as strong acid and alkali), its durability may be reduced, but in normal emergency road repair scenarios, it can provide reliable ground protection for multiple projects.