Ground protection mats play an important role in wheelchair access construction, providing a stable and flat road surface for wheelchair users to pass safely and smoothly. Here are some key points:

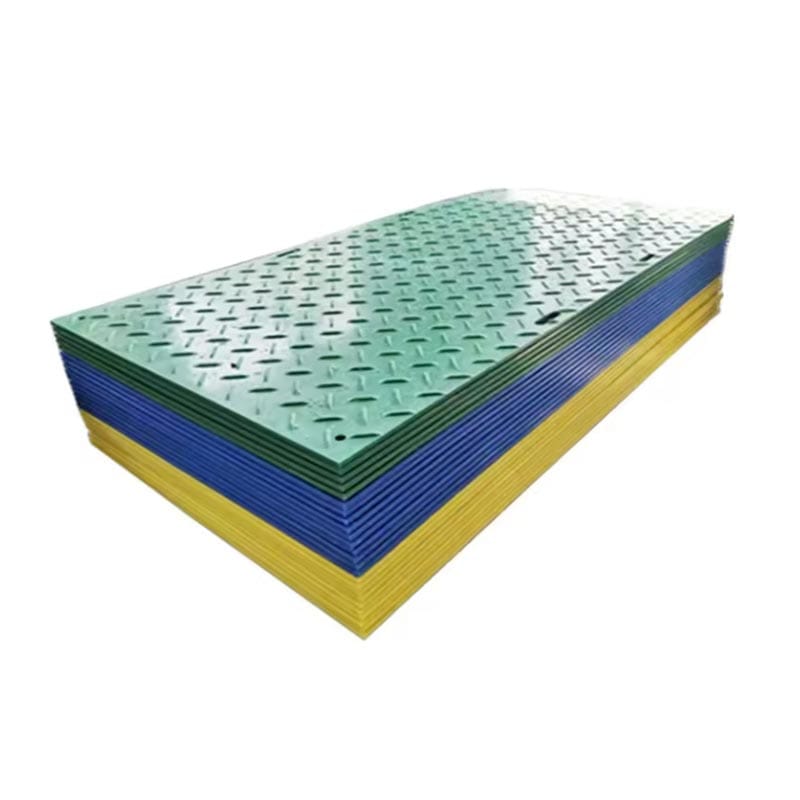

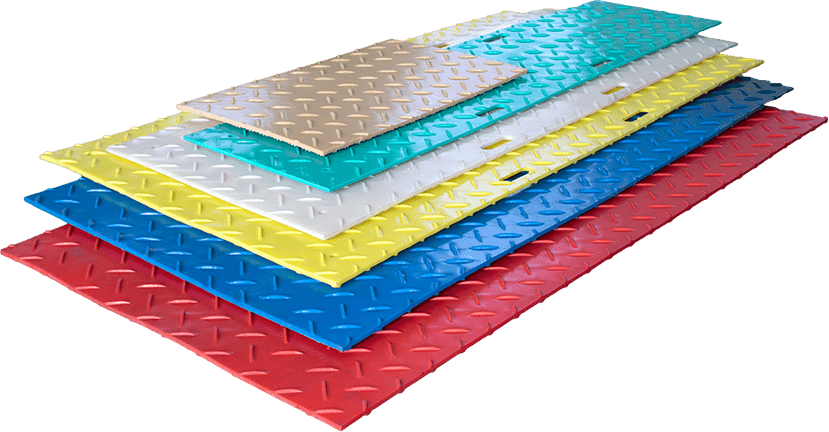

- Material selection of Ground protection mats

Rubber slabs: Strong anti-slip properties, suitable for wet environments, but relatively low durability.

Plastic slabs: Lightweight, easy to install, and can adapt to temporary or movable wheelchair access.

Metal slabs (such as aluminum alloys): High durability, suitable for long-term use, but require anti-slip design.

Concrete or composite slabs: Suitable for permanent wheelchair access, excellent stability.

- Specification requirements of Ground protection mats

Width: It is recommended to be no less than 90cm to ensure smooth passage of wheelchairs.

Slope: The slope should be controlled within 1:12 (every 1cm rise corresponds to 12cm length) to ensure that wheelchair users can get on and off easily.

Anti-slip design: The surface should have an anti-slip texture to avoid rainy days or slippery environments affecting passage.

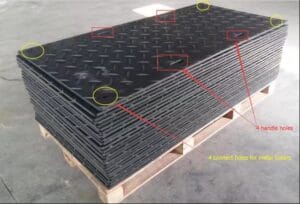

- Laying method

Fixed: suitable for permanent wheelchair access, fixed with screws, glue or concrete.

Assembly: suitable for temporary or movable access, modular splicing, easy to disassemble and move.

Folding or portable: suitable for short-term use, suitable for small ramps or threshold transitions.

- Application scenarios

Parks and scenic spots: laying barrier-free trails to facilitate wheelchair users.

Urban roads and sidewalks: provide safe wheelchair passage space and reduce obstacles.

Hospitals and shopping malls: set up barrier-free ramps to improve barrier-free accessibility.

Home entrances and exits: install portable wheelchair ramps to improve barrier-free experience.