In the wave of urban construction, construction sites are a busy and vibrant battlefield. Here, large machinery roars, construction materials are frequently transported, and workers are in a hurry. In this seemingly chaotic but orderly construction scene, the ground protection mat silently plays an indispensable role. As a temporary road, it escorts the smooth progress of the project.

1.Stable load-bearing, no fear of heavy pressure

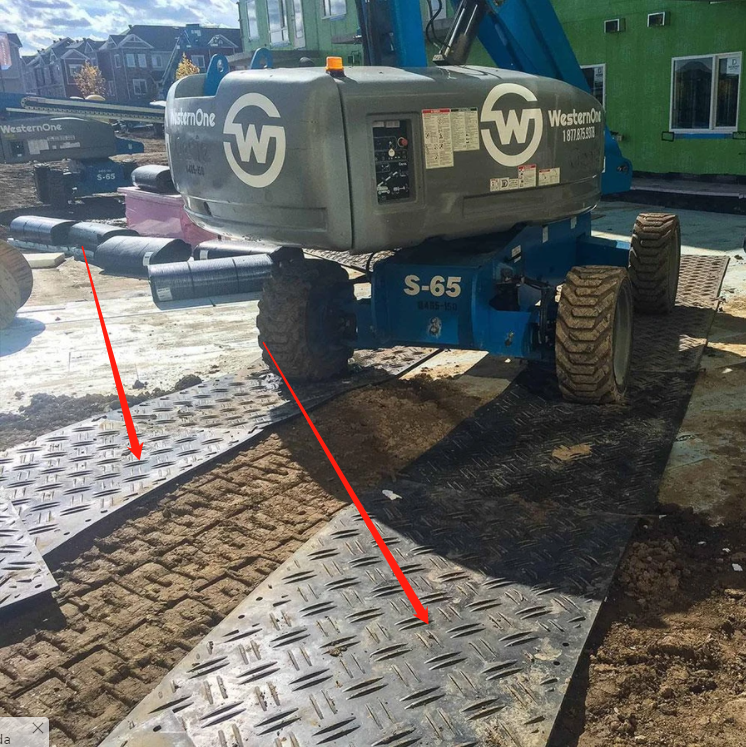

In the construction site, all kinds of heavy machinery shuttle back and forth, such as trucks loaded with steel bars, cement and other construction materials, excavators swing their giant arms to dig foundations, and cranes lift large components in the air. The weight of these machines ranges from several tons to tens of tons, exerting huge pressure on the ground. With its high-strength material and scientific structural design, the ground protection mat can evenly disperse these heavy pressures to prevent the ground from collapsing and deforming due to being overloaded. There was a high-rise residential construction site. Due to the soft soil of the site, when the protection mat was not laid, the frequent entry and exit of heavy trucks caused deep ruts on the ground, which not only affected the traffic of vehicles, but also caused a certain degree of disturbance to the surrounding newly constructed foundations. After laying the ground protection mat, this problem was effectively solved, ensuring the smooth driving of the transport vehicles and guaranteeing the construction progress.

2.Anti-skid and wear-resistant, safety guarantee

The construction site environment is complex, often covered with dirt, sand and gravel and other debris, and the ground is slippery and muddy. The surface of the ground protection mat has been specially treated and has a good anti-skid texture, which greatly increases the friction with the wheels and pedestrians’ feet, and reduces the probability of safety accidents such as slipping and vehicle rollover. At the same time, under long-term mechanical rolling and personnel trampling, ordinary ground will soon wear out, while the protective mat has excellent wear resistance and can withstand the test of harsh environment. At a bridge construction site, the construction area is close to the river, the air humidity is high, and the ground is wet all year round. When workers are carrying construction materials, they often fall and get injured because of the slippery ground. Since the laying of the ground protection mat, the number of slip accidents has been significantly reduced, and workers can work more safely and efficiently.

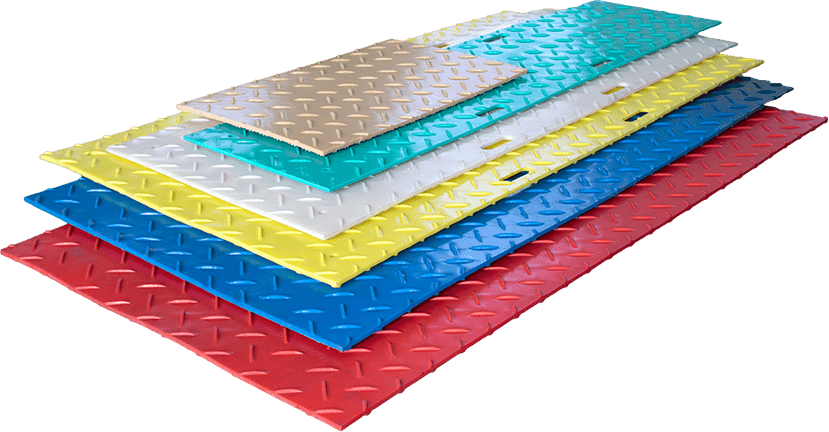

3.Quick construction, flexible and convenient

The construction area and road requirements of the construction site may change at any time. The ground protection mat is easy to install, without complicated construction processes and professional tools, and a few workers can quickly complete the laying, which greatly saves time and labor costs. Moreover, when the construction layout is adjusted and the temporary road needs to be replanned, the protection mat can be easily disassembled, transferred, and reused without wasting resources. In a commercial complex construction project, due to the adjustment of the pre-construction planning, the original temporary road needs to be relocated. If it is a traditional hardened road, it will take a lot of time and money to dismantle and re-lay it. The ground protection mat only took one day to complete the dismantling and re-laying work, ensuring the continuity of construction and avoiding delays in the construction period caused by road problems.

4.Protect the ground and reduce maintenance costs

During the construction process, the frequent operation of large machinery and the stacking of building materials can easily cause permanent damage to the original ground, such as scratches and potholes. Using ground protection mats is like putting on a layer of solid armor for the ground, which effectively avoids these injuries. After the project is completed, there is no need to spend a lot of money and energy to repair the damaged ground. Take the construction of an industrial park as an example. Since ground protection mats were used throughout the construction period, the ground of the site remained basically intact after the construction was completed. It only needed simple cleaning to be delivered for use, saving the construction party a considerable amount of ground repair costs.

As the first choice for temporary roads on construction sites, ground protection mats play an irreplaceable role in construction with their many advantages such as stable load-bearing, anti-slip and wear-resistant, convenient construction, and protection of the ground. It is a well-deserved “invisible guardian” on the construction site.