In the field of oil and gas extraction, efficient operation of the drilling site is crucial. Among them, ensuring the smooth passage of equipment and personnel and protecting the fragile surface environment have become key issues that need to be solved urgently. A set of scientific and reasonable drilling site paving solutions can not only significantly improve traffic capacity, but also effectively protect the surface, achieving a win-win situation for mining operations and environmental protection. Therefore, paving the drilling site is imminent.

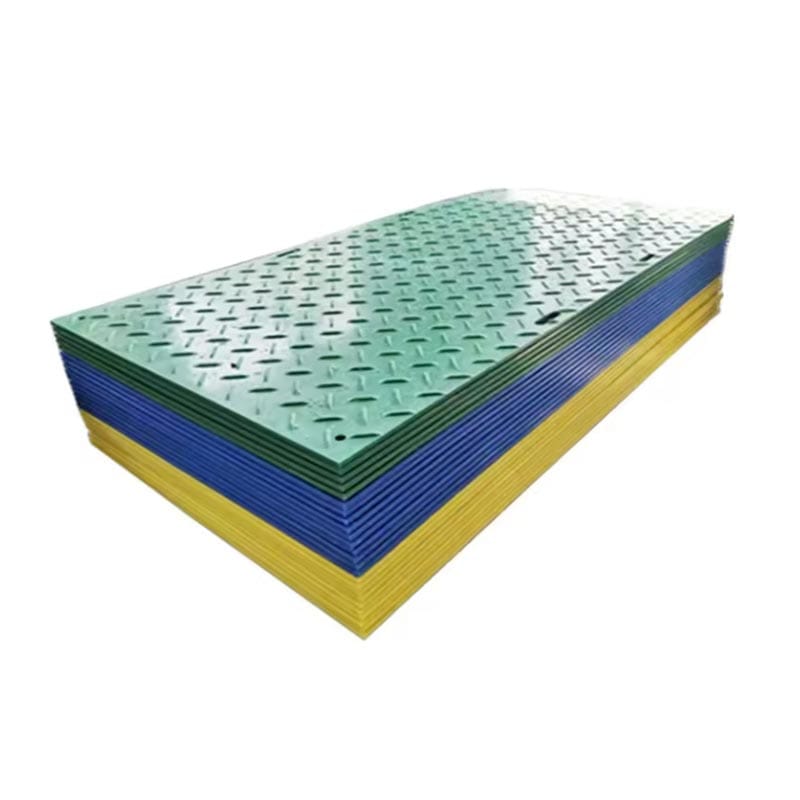

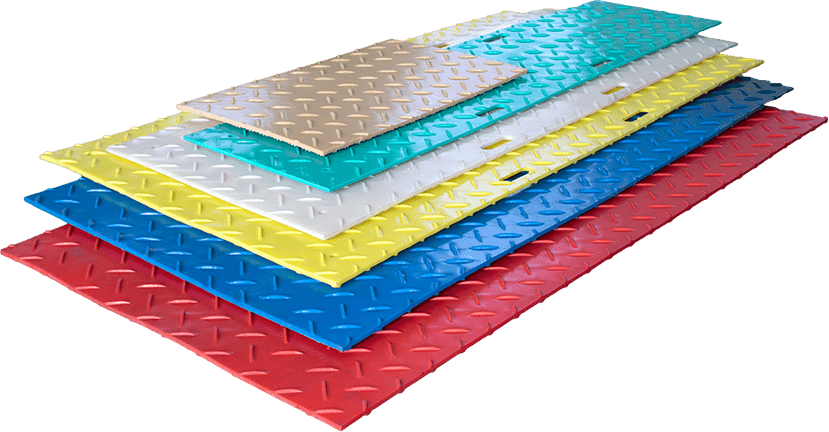

For example, prefabricated ground protection mat were used in a shale gas pre-drilling project. In view of the characteristics of the shale gas well site, the project adopted a construction method of laying a dry mortar leveling layer under the prefabricated ground protection mats instead of laying a gravel base under some prefabricated assembled ground protection matss, solving the problem of insufficient soil base flatness. Through actual engineering operations, the installation efficiency achieved the expected effect, and an average of 80 prefabricated components could be installed every day. Compared with the construction period of conventional field, the construction period of prefabricated assembled field is 4 days (excluding the maintenance period), which is reduced by 43%. If the concrete maintenance period is included, the construction period is reduced by 88%, which greatly speeds up the progress of the project.

Another option is to use a modular road system. This system consists of multiple standardized modules, which can be flexibly assembled according to the actual terrain and traffic needs of the drilling site. The modules are tightly connected to form a solid overall road surface. In the “Qieshen 1 Well” project of the Northwest Oilfield Tazhong Exploration, facing the complex terrain in the hinterland of the desert, the construction team cleverly adopted a construction method similar to the modular idea. They first used the “peeling onion” method to cut down the sand hills, and then pushed out a desert road from the middle of the lowered sand beam, and then paved anti-seepage cloth and sand and gravel for rolling. Despite the many challenges such as cold weather, large temperature difference between day and night, and difficulties in logistics supply, the construction of the 32-kilometer desert road from Qieta km to the well site was successfully completed through reasonable planning of the construction process, ensuring the smooth development of subsequent drilling operations.

In addition, laying gravel pavement is also a common and practical method. Evenly laying gravel on the ground and compacting it can effectively improve the bearing capacity of the ground. The gaps between the gravel can also play a role in drainage, preventing water accumulation on the road from affecting traffic. This solution is relatively low in cost, easy to obtain materials, and simple in construction. To a certain extent, it can not only meet traffic needs, but also protect the surface to a certain extent, reducing the direct damage to the surface by vehicles and personnel. For example, in the western capacity construction project of Sazhongnan District 1 of the Daqing Oilfield Production Plant No. 1, the drilling area is low-lying, with serious water accumulation and muddy roads during the rainy season, making it difficult for operating vehicles and personnel to pass. The youth commando team dredged more than 40 channels and paved more than 40 roads by laying gravel, effectively improving traffic conditions and clearing obstacles for early construction.

The selection of a paving solution for the drilling site needs to comprehensively consider multiple factors such as cost, construction difficulty, traffic needs, and the degree of protection of the surface. Whether it is precast concrete slabs, modular road systems, or gravel pavement, each has its own advantages and applicable scenarios. The rational use of these paving solutions can significantly improve the traffic capacity of the drilling site, ensure the smooth progress of the project, and at the same time protect the surface environment to the greatest extent, laying a solid foundation for the sustainable development of the oil and gas extraction industry.